Signals, solenoid valves, power and loads lines must be checked and monitored quickly by smart relays that ensure signal transmission in accordance with IEC 61508 standard and SIL 3 rating.

Compared to standard relays, smart safety relays enable reliable line and load monitoring, like GM International D5000 series modules. From a functional safety point of view, safely de-energized relays can be used in process automation areas that require functionally reliable shutdown according to SIL3 and IEC 61508 requirements. They safely manage offline, normally energized, and safe states. From "smart" operation point of view, these models are equipped with auxiliary inputs/outputs and communication interface. They also allow diagnostic operations such as supply voltage configuring and load resistance, checking internal coil integrity and ground fault.

Why choose a smart relay

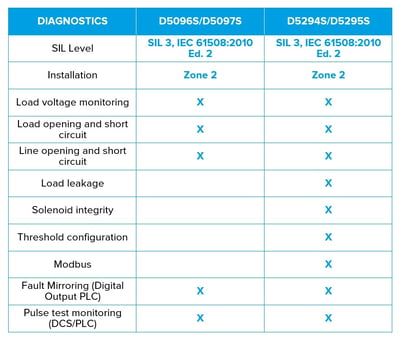

Smart relays make diagnostics available to the system. Then, compared to standard relays, they extend the available voltage and current ranges. Ultimately, they support communication technology. GM International D5294S and D5295S relays support Modbus communication on RS485 cable. Up to 127 modules can be arranged in a multi-drop network and monitored and configured from a single master unit. Each "slave" is uniquely identified by an address and, when required, makes its value available for reading/writing operations. Modbus protocol advantages are obvious: a single communication interface for all connected relays; a multidrop connection up to 1200 meters; no need for system digital inputs for alarm monitoring; availability of information about the actual fault type (while the alarm can only warn about the generic fault condition).

In some applications, fault is reflected back to the PLC or DCS that drives the solenoid. The prerequisite is that the digital output module of the drive system can set an open circuit fault threshold on the output current. This is also called mirroring functionality. It reduces the need for an additional digital fault input into the system.

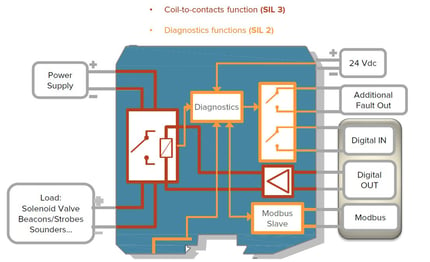

Smart relay scheme

Typical practical applications of smart relays include normally energized solenoid valves, audible and visual alarms in Fire&Gas, high availability dual coil solenoid valves, single phase load cut solenoid valves. The configuration of parameters that allow the activation of alarms as a function depending on voltage, current, and resistance is guaranteed through software. Coil integrity and driver status can also be detected via software. Real-time monitoring and data logging features are also available.

In case of a normally energized solenoid valve, where the load current is at the nominal value, the load is still energized. However, since the smart relay has lost redundancy, a fault has been forced. In case of a dual coil solenoid valve, since each coil is enough to activate a valve, the two coils prevent false tripping if only one of them opens, thus increasing availability. In this context, the smart relay can detect the opening of the single valve coil. In case of an indicator for Fire&Gas applications, if the valve is affected by a partial short circuit of the solenoid coil, it may affect its ability to activate on demand. If the measured load resistance is less than the acceptable value, the fault is reported.

These examples demonstrate how smart safety relays are the best system to ensure real-time diagnostics and complete transparency in detecting line and load anomalies.

Would you like to know more? Watch our webinar by clicking on the following link