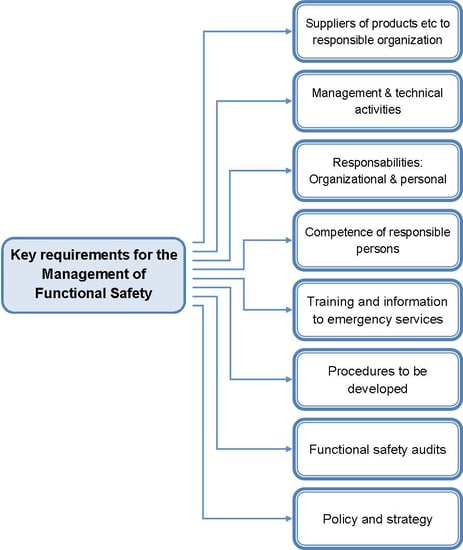

Managing functional safety includes taking on various activities and responsibilities to insure that functional safety objectives are achieved and maintained. These activities must be documented, typically in a document called the Functional Safety Management (FSM) plan.

The FSM plan should consider:

- The overall strategy and methods for achieving functional safety, together with evaluation methods and the way in which the process is communicated within the organization.

- The identification of the people, departments, and organizations that are responsible for carrying out and reviewing the applicable overall, E/E/PES, or software safety lifecycle phases (including, where relevant, licensing authorities or safety regulatory bodies).

- The safety lifecycles phases to be used.

- The documentation structure.

- The measures and techniques used to meet requirements.

- The functional safety assessment activities to be performed and the safety lifecycles phases where they will be performed.

- The procedures for follow-up and resolution of recommendations arising from hazard and risk analysis, functional safety assessment, verification and validation activities, etc.

- The procedures for ensuring that personnel are competent.

- The procedures for ensuring that hazardous accidents (or near misses) are analyzed, and that actions are taken to avoid repetition.

- The procedures for analyzing operations and maintenance performance, including periodic functional safety inspections and audit; the inspection frequency and level of independence of personnel to perform the inspection/audit should be documented.

- The procedures for management of changes.

All those responsible for managing functional safety activities must be informed and aware of their responsibilities.

Suppliers providing products or services in support of any safety lifecycle phase shall deliver products or services as specified by those responsible for that phase and have an appropriate quality management system.

Scheme of Management of Functional Safety according to IEC61508-1 (Clause 6, GMI SIL Manual)