For a successful implementation of intrinsic safety (IS) protection, in addition to standards and circuit choices, there are practices to be observed scrupulously and mistakes to be avoided.

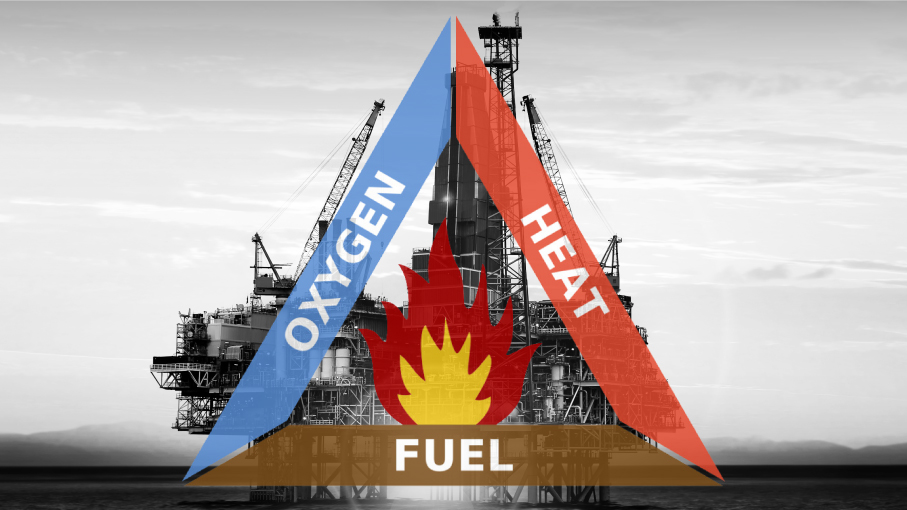

The basis from which properly implementing an intrinsically safe system is the regulatory framework. At international level, IECEx is a certification scheme for independent testing and certification of devices and services in the explosion protection industry. Many regulatory requirements are summarized in the IEC 60079 series, but also in the American standard NFPA 70 which contains a complete set of requirements for electrical installations and in CSA C22 that represents the standard for the Canadian market. From a technological point of view, intrinsic safety is the main technique for preventing fire and explosion risks caused by electrical equipment and electronic instruments. At the circuit and energy level it is mainly guaranteed by Zener barriers and Galvanic isolators. Zener barriers are among the most successful devices in providing intrinsic safety. These are passive protection interfaces, based on Zener diodes, used to limit the amount of energy and current flowing in hazardous areas in the event of a fault, overvoltage, short circuit, etc. Galvanic isolators allow the signal to pass from the source to the measuring device via transformers, or optical or capacitive couplers. In addition to interrupting ground loops, isolation interrupts high voltage spikes and eliminates high common mode voltages, protecting operators, and control and measurement devices. Let's see six main mistakes to avoid when designing and implementing an intrinsically safe system.

First mistake: not providing a dedicated ground connection

In order to be intrinsically safe, Zener barriers require a dedicated ground connection that has to be maintained over time. The connection resistance between the ground of the Zener barrier and the furthest one from the reference point needs to be at no more than 1 Ohm to avoid possible ignitions. A good ground connection must ensure that the fault current returns to the safe area by preventing any voltage and current rise at the hazardous area terminals. This condition is allowed by the use of a dedicated grounding conductor which must be separated from any other system’ structural ground wire and connected at a single reference point.

Second mistake: not maintaining distances between intrinsically safe circuits

Maintaining distances in intrinsically safe circuits is critical. The application of this method allows to segregate intrinsically safe circuits from those that are not, to segregate different intrinsically safe circuits, and to prevent that components on which intrinsic safety depends are not short-circuited. Typically, terminals for connecting external intrinsically safe circuits should be installed so that the distance to non-intrinsically safe circuit conductors is at least 50 mm. The goal is to implement the circuit in such a way that safety-critical components are not bypassed by short circuits. The minimum distances for components, as well as the displacement of components and their connections, are compared to the regulatory limits of intrinsic safety.

Third mistake: failure in identifying Ex enclosures

For obvious safety reasons, an enclosure that houses intrinsically safe circuits should be clearly identified by providing a warning label. Typically, it is accepted that the color blue identifies intrinsically safe circuit sections. EN60079-14 states that "Intrinsically safe circuits shall be marked to identify them as parts of an intrinsically safe circuit. If the conduits or coatings are marked with a color, it shall be light blue."

Fourth mistake: failure in identifying intrinsically safe Ex cables

Control cables with blue sheathing and conductor insulation are easily identified. They are used in hazardous areas for intrinsically safe circuits and meet EN 60079-14 requirements: "When intrinsically safe circuits have been identified with light blue cables, such cables shall not be used for other purposes in a manner or location likely to cause confusion or reduce the effectiveness of identification of intrinsically safe circuits." However, it is good practice to ensure that cables exiting from enclosures are designed to limit stresses on cable glands and terminals. The junction box should be positioned so that cables can exit with an adequate bend radius.

Fifth mistake: incorrect cable gland selection or installation

Cables connection to electrical equipment shall be made by means of selected cable glands considering the type and diameter of cable used and maintaining the integrity against explosion protection. Cable glands must secure the cable in such a way that applied tension or twisting is not transmitted to conductor connections. Intrinsically safe cable glands shall have impact protection and may be used to make an electrical connection from the outside in a fireproof enclosure. Cable-free line bushings, so-called blind plugs, may be used for internal sealing of explosion-proof enclosures.

Sixth mistake: missing descriptive documentation

Missing descriptive documents for intrinsically safe systems makes it problematic to classify plants, identify systems and components, monitor compliance, and verify coordination activities. Collecting documents that demonstrate electrical equipment and systems comply with regulations is a key step. Circuits and systems used in hazardous areas must be verified in order to have characteristics compliant with the descriptive documentation.

Would you like to know more? Watch our webinar "Intrinsic safety, six common mistakes"