PT100 sensors are critical components in temperature measurement systems.By following proper calibration and testing procedures, PT100 sensors can provide dependable temperature data vital for industrial processes, research, and quality control applications. One of our Customers, a global machine builder in various sectors such as pharmaceuticals, etc. needed a device that provided an alarm contact once the temperature of the PT100 exceeded the temperature manually set via the potentiometer.

Challenge

The customer needed a device capable of triggering an alarm contact when the temperature recorded by the PT100 surpasses the threshold manually set via the potentiometer. This alarm contact would subsequently activate a light signal. Additionally, the customer expressed a desire to have visibility of the set threshold value.

Solution

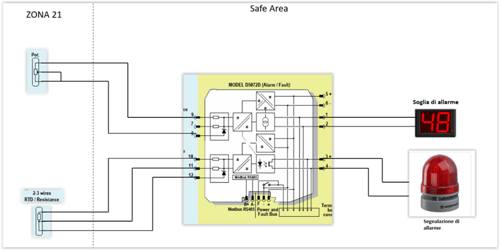

The customer's application involves a mill for sieving powders in an area with ATEX zone 21 certifications. Specifically, after sifting the powders (ZONE 21), an RTD (PT100) was positioned to monitor the temperature of the air to ensure that it remained below the threshold designated for certified areas. We designed a solution to meet the customer's need to manually adjust an alarm threshold (from 30 to 120°C) using a potentiometer and to compare the set temperature with that detected by the PT100. This solution involved the software modification of a D5072D, an intrinsically safe SIL2 multifunction temperature converter. In this device, the potentiometer was integrated into the first channel, for which we built an ad hoc customized table to accommodate the full-scale values of the measurement. Since the potentiometer operated linearly, no additional points were needed in the table. Meanwhile, the PT100 sensor occupied the second channel, accurately monitoring the field temperature.

By using the barrier in the "Fault Out" configuration, it is possible to obtain an output alarm contact to drive the required light signal. The alarm threshold is set high with a trip value of zero, which also calculates the difference between the values measured at the two inputs. This setting allows us to obtain the comparison of the two inputs, meaning that the output switches when the temperature of T2 (RTD) exceeds that of T1 (Potentiometer).

Furthermore, it will be possible to display the potentiometer set temperature on the monitor by connecting to the analog output of the first channel. It has also been possible to propose to the customer the acquisition of other requested data via Modbus.

Benefits

The customer benefits from technical consultancy services offered by GM International, that provided a customized solution to meet the specific needs of the customer, ensuring that the device aligned perfectly with their unique application requirements. Furthermore, the solution provided ensured compliance with industry standards and regulations, such as ATEX zone 21 certifications, guaranteeing safety and adherence to guidelines in sensitive areas. The solution eliminated the need for manual adjustment of alarm thresholds on the barrier, streamlining operations, reducing the risk of errors, and reducing the costs of the application, which initially required the use of multiple devices to achieve the goal.