GMI D5072D SIL 2 Temperature Signal Converters have been used by an important US organization (NSO) to monitor thermocouples mounted to the heat stop of the Daniel K. Inouye solar telescope (DKIST).

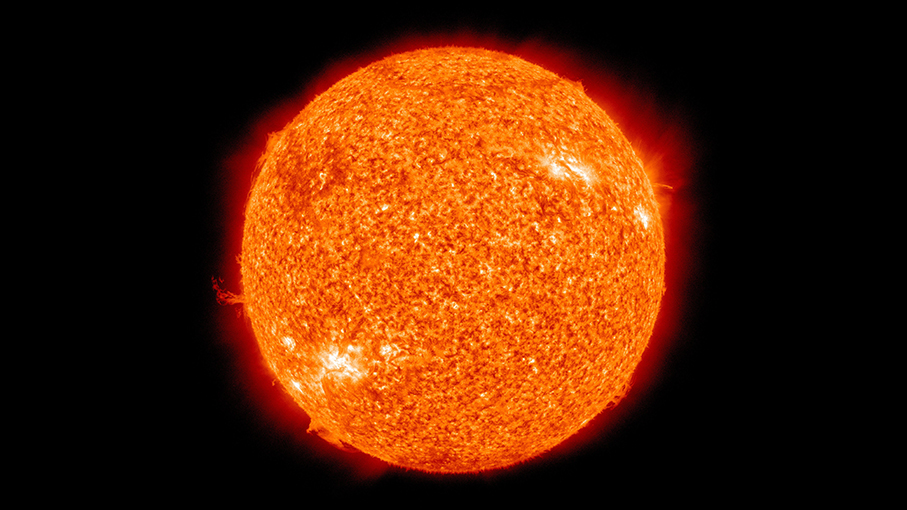

The Daniel K. Inouye Solar Telescope (DKIST) is a scientific facility for studies of the Sun at Haleakala Observatory on the Hawaiian island of Maui. It is the world's largest solar telescope, with a 4-meter aperture.

The National Solar Observatory (NSO) is a US organization dedicated to ground-based optical astronomy. NSO builds and manages a range of one to four-meter telescopes. DKIST is a solar telescope, so thermal management is very important because pointing a four-meter mirror directly at the Sun presents many challenges and the most important one is to control the heat. In fact, the generation of a huge amount of heat requires innovative cooling strategies to avoid damaging delicate telescope equipment and the building it lives in. The four-meter primary mirror collects and reflects about 12 kW of solar thermal energy. Maintaining sharp, high-quality images mean that the telescope’s optics need to be kept at near ambient temperature. The instruments cannot handle that much heat directly, so the first thing the reflected beam touches is a heat stop, which absorbs about 98% of the heat.

GMI D5072D SIL 2 temperature signal converters are used to monitor thermocouples that are mounted to the heat stop and the structure surrounding it. Most of D5072D modules are for monitoring, some of them are used for safety functions which will trigger actions to block the light path (cover the primary mirror) in the case of overheating, in order to protect the expensive optical coating on the heat stop.

D5072D SIL 2 Multifunction Temperature Converter

The Multifunction Temperature Converter D5072 accepts a low level DC signal from millivolt, thermocouple or 2-3-4 wire resistance/RTD or transmitting potentiometer sensor, located in Hazardous Area, and converts, with isolation, the signal to drive a Safe Area load, suitable for applications requiring SIL 2 level in safety related systems for high risk industries. Output signal can be direct or reverse. Modbus RTU RS485 output is available on Bus connector. Cold junction compensation can be programmed as Internal provided by an internal temperature sensor. Fixed to a user-customizable temperature value or Remote connecting compensation RTD to one of the two channels. Duplicator function provides two independent outputs from one single input. Output can be configured as adder, subtractor, low/high selector. Modules are provided with alarm function, which is available via photoMOS output.

FEATURES

- SIL 2

- Input from Zone 0/Div. 1

- Installation in Zone 2/Div. 2

- mV, TC, 2/3/4wire res./RTD or potentiometer input

- Duplication/inversion/scaling/custom output • Selectable CJC: internal PT1000, external RTD or fixed

- Fastest integration time: 50 ms

- Burnout/internal/cjc/in sensor fault monitor

- Alarm output with user-settable trip points

- Modbus RTU RS-485 for monitor & configuration

- Fully programmable operating parameters

- High Accuracy, µP controlled A/D converter

- Three port isolation, Input/Output/Supp

For more information you can visit D5072D product page clicking here